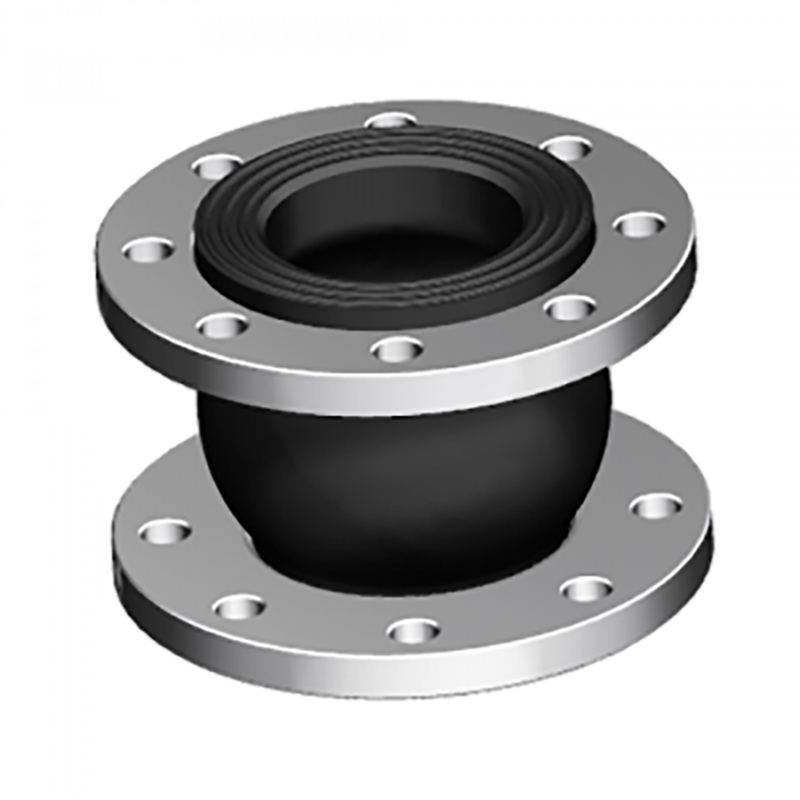

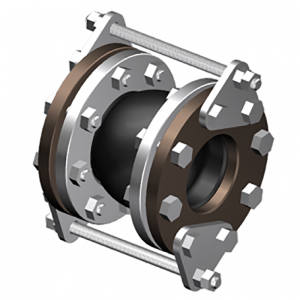

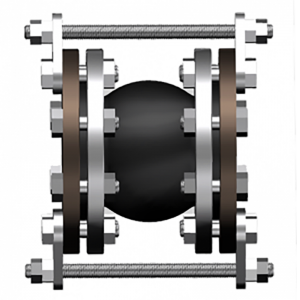

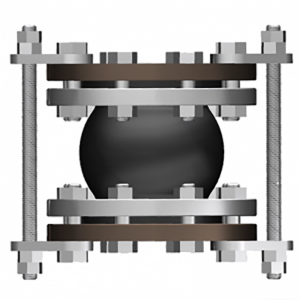

18 Years Factory China Best Quality Wholesale Custom Cheap Heavy Duty Rubber Expansion Joint Double Ball Rubber Joint

Sticking to the principle of “Super High-quality, Satisfactory service” ,We are striving to generally be a very good business partner of you for 18 Years Factory China Best Quality Wholesale Custom Cheap Heavy Duty Rubber Expansion Joint Double Ball Rubber Joint, We are able to give you quite possibly the most competitive rates and good quality, because we’re much additional Skilled! So make sure you will not wait to contact us.

Sticking to the principle of “Super High-quality, Satisfactory service” ,We are striving to generally be a very good business partner of you for China Rubber Bellow, Flexible Rubber Joint, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to to suit your needs of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We’re confident that we’re going to have a bright prospect and to be distributed all over the world in the years to come.

Details

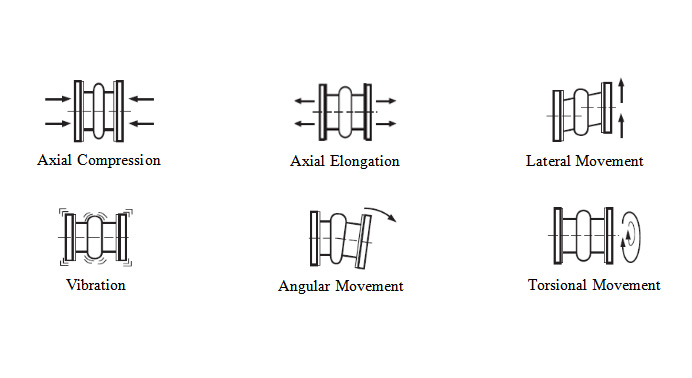

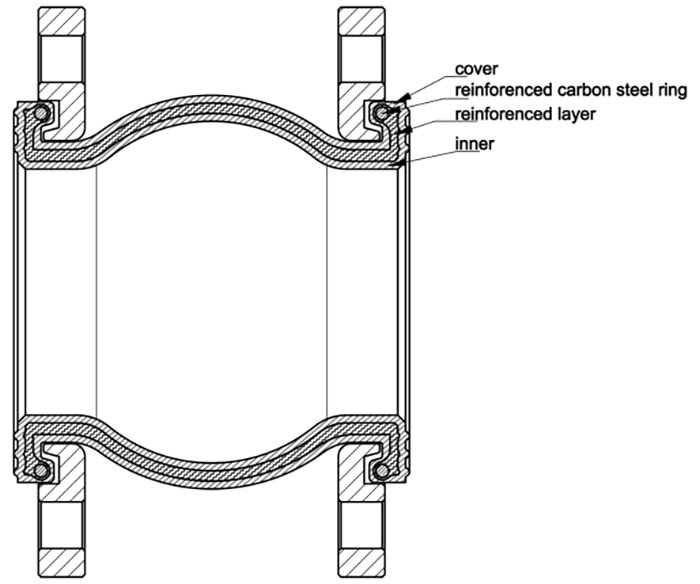

The single-arch product can reduce the vibration and noise, which can also solve the axial/lateral/angular movements/eccentric problems. Reinforcement layer of the bellows by Nylon cords and at both ends by hardened steel wire rings. The floating steel flanges are drilled according to DIN, ANSI, BS, JIS and other standards. If the piping pressure is much higher, reinforced bolts should be assembled together with flanges.

| Specifications | I | II | III |

| Working Pressure Mpa (Kgf/Cm2) | 1Mpa (10) | 1.6 (16) | 2.5 (25) |

| Test Pressure | 1.5Mpa | 2.4Mpa | 3.75Mpa |

| Burst Pressure Mpa (Kgf/Cm2) | 3 (30) | 4.8 (48) | 5.5 (55) |

| Vacuum Kpa (Kgf/Cm2) | 53 (400) | 86(660) | 100 (750) |

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN600 (1/2″-24″) | ||

| Connection Method | FLANGETHREADCLAMP | ||

| Flanges Dimensions | DIN, EN,ANSI, BS, JIS and other standards | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | Flange, Thread | ||

| Flange Material: | Carbon Steel, Stainless Steel | ||

| Period of Delivery | about 21 working days | ||

|

Single Arch-Standard Length |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Standard O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

135 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

205 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

240 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

265 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

Single Arch-130MM |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

1 1/2″ |

40 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2″ |

50 |

130 |

30 |

20 |

20 |

35° |

16(225) |

660(26) |

|

2 1/2″ |

65 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

3″ |

80 |

130 |

30 |

20 |

20 |

30° |

16(225) |

660(26) |

|

4″ |

100 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

5″ |

125 |

130 |

30 |

20 |

20 |

25° |

16(225) |

660(26) |

|

6″ |

150 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

8″ |

200 |

130 |

30 |

20 |

20 |

15° |

16(225) |

660(26) |

|

10″ |

250 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

12″ |

300 |

130 |

30 |

20 |

20 |

10° |

16(225) |

660(26) |

|

Single Arch-American Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. (psi)-3,-4 |

Max Vacuum (in. of Hg)-5 |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1″ |

25 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

37° |

225 |

26 |

|

1 1/4″ |

32 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

31° |

225 |

26 |

|

1 1/2″ |

40 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

27° |

225 |

26 |

|

2″ |

50 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

20° |

225 |

26 |

|

2 1/2″ |

65 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

17° |

225 |

26 |

|

3″ |

80 |

6″ |

1/2″ |

3/8″ |

±1/2″ |

14° |

225 |

26 |

|

4″ |

100 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

14° |

225 |

26 |

|

5″ |

125 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

11° |

225 |

26 |

|

6″ |

150 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

9° |

225 |

26 |

|

8″ |

200 |

6″ |

3/4″ |

1/2″ |

±1/2″ |

7° |

225 |

26 |

|

10″ |

250 |

8″ |

1″ |

5/8″ |

±3/4″ |

7° |

225 |

26 |

|

12″ |

300 |

8″ |

1″ |

5/8″ |

±3/4″ |

6° |

225 |

26 |

|

14″ |

350 |

8″ |

1″ |

5/8″ |

±3/4″ |

5° |

150 |

26 |

|

16″ |

400 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

18″ |

450 |

8″ |

1″ |

5/8″ |

±3/4″ |

4° |

150 |

26 |

|

20″ |

500 |

8″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

24″ |

600 |

10″ |

1″ |

5/8″ |

±3/4″ |

3° |

150 |

26 |

|

Single Arch-Jis Standard |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

Special O’all Length(mm) |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

inch |

inch |

inch |

inch |

|||

|

1 1/4 |

32 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

1 1/2 |

40 |

125 |

10 |

6 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 |

50 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

2 1/2 |

65 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

3 |

80 |

125 |

10 |

7 |

10 |

10° |

16(225) |

700(86Kpa) |

|

4 |

100 |

150 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

5 |

125 |

175 |

10 |

10 |

10 |

7° |

16(225) |

700(86Kpa) |

|

6 |

150 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

8 |

200 |

200 |

10 |

12 |

10 |

5° |

16(225) |

700(86Kpa) |

|

10 |

250 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

12 |

300 |

250 |

10 |

15 |

10 |

5° |

16(225) |

700(86Kpa) |

|

Single Arch-Domestic Market |

||||||||

|

Dimensions |

Movement Distance |

Operating Condition |

||||||

|

Pipe Size |

O’all Length |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

Max w.p. bar(psi) |

Max Vacuum (mm hg) / Kmpa |

|

|

Inch |

mm |

mm |

mm |

mm |

mm |

|||

|

1 1/4″ |

32 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

1 1/2″ |

40 |

95 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2″ |

50 |

105 |

10 |

6 |

10 |

25° |

16(225) |

700(86Kpa) |

|

2 1/2″ |

65 |

115 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

3″ |

80 |

135 |

15 |

8 |

12 |

25° |

16(225) |

700(86Kpa) |

|

4″ |

100 |

150 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

5″ |

125 |

165 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

6″ |

150 |

180 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

8″ |

200 |

210 |

20 |

12 |

16 |

15° |

16(225) |

700(86Kpa) |

|

10″ |

250 |

230 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

12″ |

300 |

245 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

14″ |

350 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

16″ |

400 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

18″ |

450 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

20″ |

500 |

255 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

|

24″ |

600 |

260 |

30 |

14 |

25 |

8° |

16(225) |

700(86Kpa) |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang